Equipment

All piping, valves, fittings, tubes, gauges, and other apparatuses intended to be used in an experiment with hydrogen must be specifically designed and tested for use with hydrogen. Likewise, specific techniques and rules for connecting hydrogen-containing elements must be followed. Whenever high pressure is involved, the use of specific fittings rated for appropriate pressure is required. Various standards, including ASME B31 (Pressure Piping), describe the requirements and certifications for pressurized equipment. Due to the very small size of the hydrogen molecule, hydrogen is the most leak-prone of gases and will also permeate through materials that can contain other gases. Do not assume that general lab equipment is suitable for hydrogen!

Items such as pressure regulators and relief valves are of particular importance and must be specifically rated for hydrogen service at the planned pressure. Plastic tubing should be avoided, even at low flows and pressures, as it is susceptible to damage and may be flammable.

A best practice is to assure (using a HAZOP assessment, for example) that all elements of a hydrogen system can be safely vented and purged for service and repair and that pressure cannot be trapped in an area of the system with no pressure relief in the event of another failure.

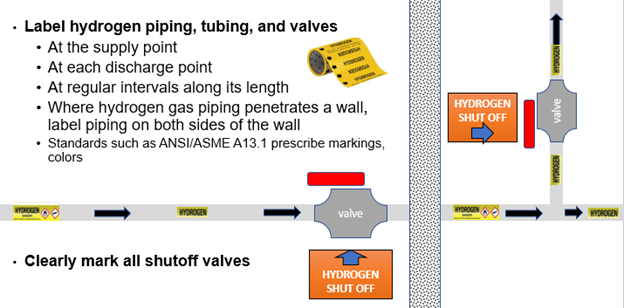

Clear labeling of pipes, valves, and components that contain hydrogen provides personnel with immediate visual references to minimize accidental improper operation and to assess any problems that arise (see figure below).