Evaluating Metals

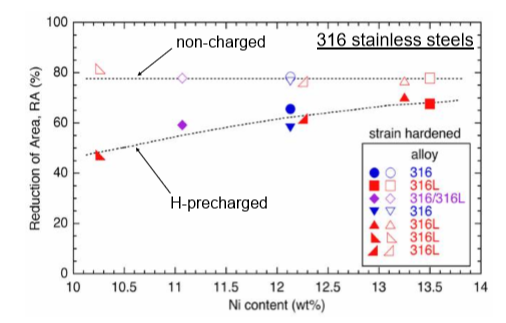

Plot showing the RRA as approximately 0.9 for the 316 stainless steels when nickel content is 13%

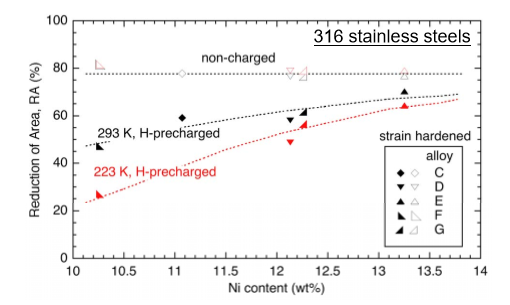

Plot showing temperature has a pronounced effect on the reduction of area measured for 316 stainless steels in hydrogen, particularly at lower nickel content

References

ANSI/CSA CHMC 1-2014 - Test Methods For Evaluating Material Compatibility In Compressed Hydrogen Applications - Metals

Technical Reference For Hydrogen Compatibility of Materials – Sandia National Laboratory

ASME STP/PT-003, Hydrogen Standardization Interim Report for Tanks, Piping, and Pipelines

ASME STP-PT-006 Design Guidelines for Hydrogen Piping and Pipelines