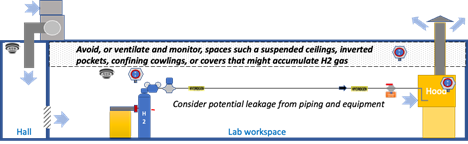

Ventilation

See more detail on H2 leak and flame detection systems in CHS Course B1: Facility Design and Construction

References

ANSI/AIHA Z9.5 Laboratory Ventilation

ASTM E84 - Standard Test Method for Surface Burning Characteristics of Building Materials

NFPA 255, Standard Method of Test of Surface Burning Characteristics of Building Materials

NFPA 45, Standard on Fire Protection for Laboratories Using Chemicals

NFPA 91, Standard for Exhaust Systems for Air Conveying of Vapors

OSHA 1910.106 - Flammable liquids

UL 723 - Standard for Test for Surface Burning Characteristics of Building Materials