- Home

-

Resources

- Center for Hydrogen Safety

- Hydrogen Fuel Cell Codes and Standards

- Learnings & Guidance

- Paper & References

- Web-based Toolkits

- Workforce Development

- Contact

- About H2Tools

- Welcome to the Hydrogen Tools Portal

- helpdesk@h2tools.org

Hydrogen

Safety Panel

Learn what the HSP is all about

HSP

What We Do

Our Focus Areas

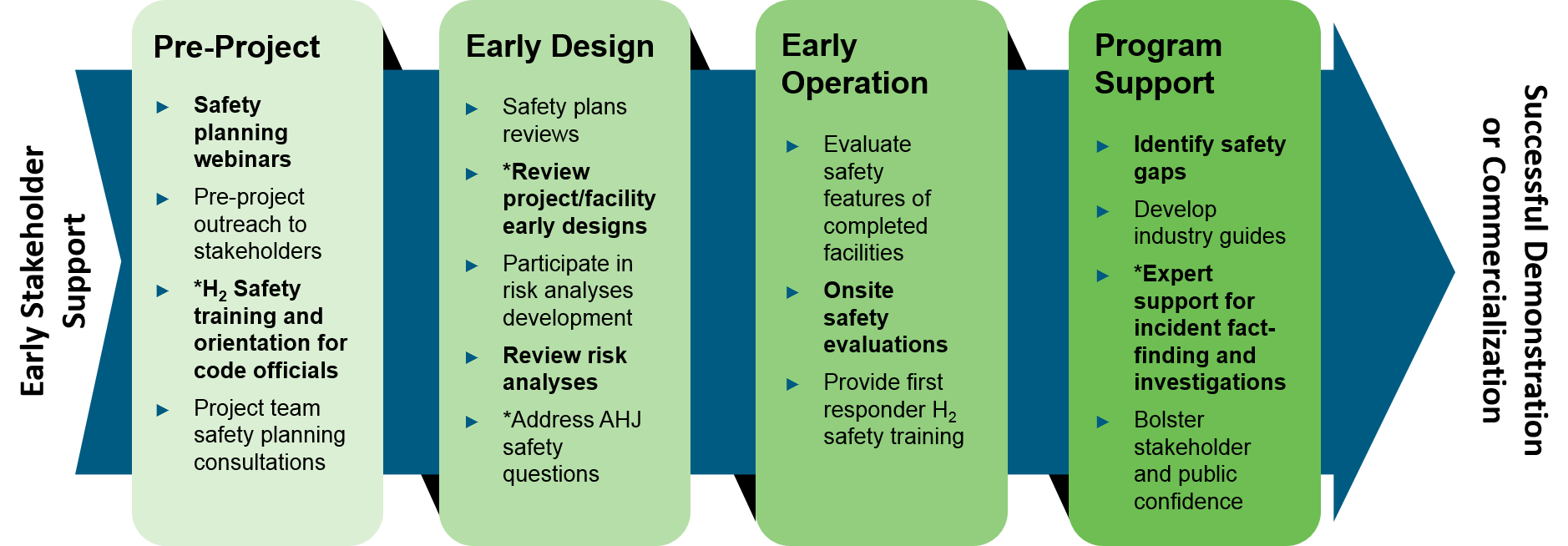

Activities Benefiting from our Involvement

* Support for AHJ and code officials can bridge the gap for inexperienced staff, facilitate faster approvals, support a greater confidence in project safety and provide more technically justified safety features or alternate means and methods.

Mission Statement

We are committed to enable the safe and timely transition to hydrogen and fuel cell technologies by sharing the benefit of extensive experience and providing suggestions and recommendations pertaining to handling and use of hydrogen.

- Hydrogen Safety Panel

Why You Need Us

Clear Safety Issue Hurdles to H2 Project Acceptance

Identify and Close Safety Gaps

Leverage Best Practice Learnings

Reduce H2 Project Cost

What We Accomplished

615

Reviews

441

Projects

200+

Presentations

15

Guides

Highlighted Projects:

For the California Energy Commission

- Light-duty Hydrogen Fueling Station Infrastructure

- Hydrogen Production Facilities

- Medium and Heavy-duty Hydrogen Infrastructure

Hydrogen Safety Project Reviews for the US Department of Energy Hydrogen and Fuel Cell ProjectsHydrogen Safety Project Reviews for the Center for Hydrogen Safety - Examples include:

- Chevron Hydrogen Co-firing Project HAZOP

- ACES/Mitsubishi HAZOP

- Constellation Power HAZOP

Utilizing the HSP

If you have interest in utilizing the expertise of the Panel, contact us by email at hsp@h2tools.org. To request services from the Hydrogen Safety Panel, please submit a request form.

Who We Are

2003 Year Established

23 Panel Members

600+ Years of Experience

Members

We are professional and reliable provider since we offer customers the most powerful and beautiful themes. Besides, we always catch the latest technology and adapt to follow world’s new trends to deliver the best themes to the market.

Contact info

We are the leaders in the building industries and factories. We're word wide. We never give up on the challenges.

- 2 Queen Street,California, USA

- (+84) 04 123 456

- :Helpdesk@h2tools.org