Isolating and Limiting Hydrogen Sources in an Emergency

In a lab emergency, it is best practice to isolate and limit the supply of hydrogen to an experiment, apparatus, and facility. Limiting or removing the hydrogen source can minimize the potential and extent of a serious fire or explosion when the unexpected happens. Remember, removing the source of fuel (hydrogen) is the easiest leg of the Fire Triangle (i.e., fuel, oxygen, and heat) to interrupt.

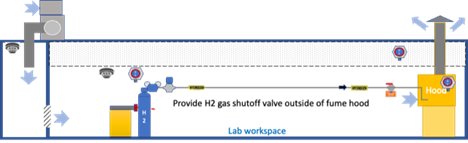

For a simple attended benchtop experiment using a single pressurized hydrogen gas cylinder, a 90 degree shutoff ball valve on the H2 supply line running to the vent hood or apparatus is a recommended and simple safety measure. Locate the valve outside of a fume hood and near the gas cylinder, where it will be very easy to reach, and away from the apparatus under test.

Of course, a manual hydrogen shutoff is only effective when a researcher is present and aware of an impending hazard. A more robust layer of protection is an automatic shutoff valve interlocked with apparatus and laboratory safety alarms, such as fire, loss of ventilation, H2 leak detection, or manual emergency stop switch. Locate the automatic shutoff valve as close to the hydrogen source as is practical to address the possibility of a hydrogen supply line failure. The valve must automatically close upon loss of actuation power, either through your safety control system, your facility alarm system, or a power outage.

It is best practice to locate the hydrogen shutoff valve or alarm on the area escape path – don’t require reentry into a hazardous area to shut off hydrogen. Clearly label as “hydrogen shutoff” or similar, and make sure personnel and emergency responders know about location and use.

Your safety and emergency plans should include instructions on emergency hydrogen shutoff activation as well as when it is deemed safe to restore gas supply.

Select shutoff valves that are compatible with the hydrogen use and select valve actuators rated for the environment that could be hazardous in the event of a hydrogen leak. Best practice includes limiting hydrogen flow to only what the apparatus requires, reducing risk of a significant hydrogen release should a line break or equipment fail. Use the smallest size supply line, regulate supply pressure, install flow-restricting orifices, or adjust flow throttling valves to limit hydrogen flow to just what is needed. Excess flow valves may also be considered if the device is properly sized for the anticipated hydrogen flow and a line break is anticipated.