Hydrogen Safety Planning

Safety in hydrogen research is maintained through a disciplined safety planning process that inherently identifies hazards and works to eliminate and reduce them. Safety planning guidance from the Hydrogen Safety Panel can be found here.

Best practice is to review safety plans with all lab participants, your organization’s safety experts, and impartial hydrogen experts such as the Hydrogen Safety Panel.

Effective safety planning starts early with good documentation. The design documents for a hydrogen experiment or process should include at a minimum a process and instrumentation diagram detailing the components, process flows, and safety elements in the equipment used; a single-line diagram outlining the controls and safety shutdowns used; and manufacturer’s information for the specifications and classifications of the equipment used. Documentation best practice includes a narrative description of design intent and operating procedures.

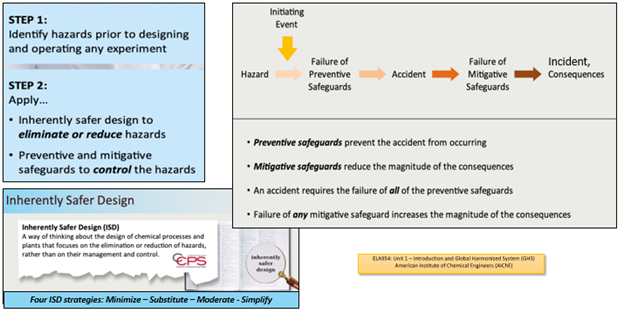

Next, a risk assessment of your experiment or process is needed to identify the inherent hydrogen hazards present in your design and the effectiveness, or absence, of design safeguards for preventing or mitigating (reduce) hazards. Several risk assessment techniques such as process hazard analysis, hazard of operations analysis (HAZOP), or failure mode and effects analysis may be used; the figures below describe the general risk assessment steps in each and define preventative and mitigative safeguards.

Update your initial safety plan with your risk assessment and update experiment design with any revised safeguards that are identified. Best practice is to revisit and update your safety plan throughout the project stages, from concept through operation.

The following key lab and experiment/process design topics are addressed in more detail below:

- Isolating and limiting hydrogen sources in an emergency

- Reducing H2 lab inventory with small-capacity hydrogen generators

- Facilitating regular H2 lab inspections using a safety checklist

- Addressing lab areas that might accumulate hydrogen gas (avoid, or ventilate and monitor, spaces such a suspended ceilings, inverted pockets, confining cowlings)