Compressed Gas Piping Systems

Recommendations for compressed gas piping systems include the following:

- Piping systems should conform to a recognized code such as ASME B31.1 Power Piping, ASME B31.3 Process Piping, or ASME B31.12 Hydrogen Piping and Pipelines.

- To prevent leaks when exposed to an external fire, the piping system should be fire resistant.

- The piping material should be selected for robustness, low permeability, and fire resistance. The material chosen should be specifically rated or approved for use with hydrogen at the planned pressure.

- Optimum material selection depends on:

- The temperature range

- The pressure

- Purity and cleaning requirements

- Installation factors (structure, environment)

- In most instances, austenitic stainless steels such as Type 304 or 316 are satisfactory for end use applications.

- See Material Compatibility for more information regarding material selection.

Piping system for hydrogen transport

(Department of Energy Fuel Cell Technology Program)

- Design of the piping system should consider ways to facilitate internally cleaning the piping when needed.

- Considerations for underground piping include:

- External corrosion

- Protection from inadvertent excavation

- Preventing hydrogen from entering an enclosed space if a leak occurs

- Using only welded joints

- Alternates to direct burial of piping include:

- Route the pipe in open trenches with removable grating so that it can be inspected and maintained.

- When pipe can be routed without any mechanical joints, place the pipe in a corrosion resistant sleeve that is open at both ends.

- Piping should not be left open to the atmosphere. Openings should be plugged, capped, or flanged or routed to a vent stack.

- To assure dispersion of small leaks, piping should be routed outdoors whenever possible.

- Piping should be routed so that it is:

- Not covered by wall, floor, or ceiling finishes

- Readily available for visual inspection and leak detection, and

- Protected from physical damage

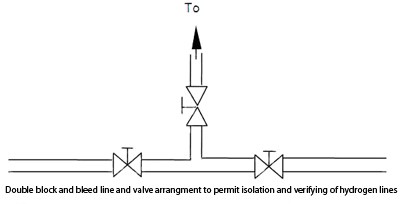

- The hydrogen system should have the necessary connections for isolating, venting, purging and leak testing, along with those needed to prepare the equipment for maintenance.

- When part of the system will remain operational while another part needs work, consider a double block and bleed arrangement to isolate active parts of the system from equipment being maintained and to facilitate purging.

Double Block and Bleed Line

Regardless of system design, a procedure for purging any piping to remove all air, moisture, or oxidizing gas or substance must be developed and documented.

References

ASME B31.1 Power Piping

ASME B31.3 Process Piping

ASME B31.12 Hydrogen Piping and Pipelines

CGA G-5.4 - Standard for Hydrogen Piping Systems at User Locations

CGA G-5.6 (EIGA Doc 121), Hydrogen Pipeline Systems

ANSI/AIAA G-095 Guide to Safety of Hydrogen and Hydrogen Systems

IGC Doc 121/04/E, Hydrogen Transportation Pipelines (pdf, 562 kb)

NFPA 55, Compressed Gases and Cryogenic Fluids Code