Hydrogen Venting and Stack Design

Regarding ignition in hydrogen vents, is there a set of conditions or operating scheme that can be used to default to the requirements of CGA 5.5 Section 6.2.4 instead of performing the thermal radiation calculations? Is there a simplified method for making this determination? As an example, if the vent is only a small bleed valve between block valves, is it acceptable to use the requirements of 6.2.4 such as 10 ft above grade?

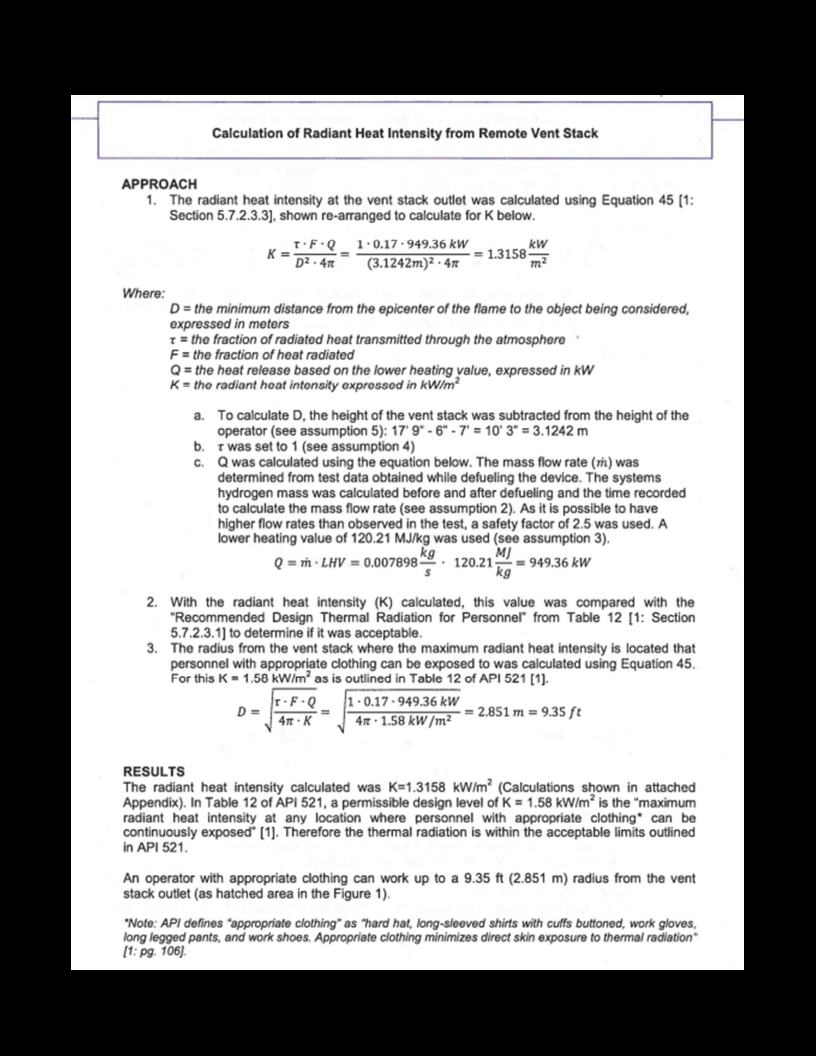

As is mentioned in the question, it should always be assumed that vent stack fires will occur. The vent stack must be designed to withstand a possible deflagration and the heat from a continuous vent stack fire. The stack should also have sufficient height and be located such that thermal radiation is safe for surrounding personnel, equipment, and buildings. The codes and standards have prescriptive and performance-based approaches. In most cases, the designer can use the prescriptive approach (i.e., the 10 ft above grade) rather than performance based (meeting API 521 thermal radiation guidelines). The example of the bleed valve is a good example where that is likely appropriate. In CGA G-5.5, both approaches are shown. However, each vent stack design should be evaluated to decide if there is a risk of high flow that might require a larger or taller stack. In general, apply the prescriptive approach to the lower flow vent systems and check the radiation via API 521 for the higher flow/high risk stacks and increase the height accordingly. See example below for calculations.