In what circumstances, such as specific flow rates, would you suggest flaring LH2 instead of venting it?

Generally flaring is not recommended. Normally GH2 is not flared for most hydrogen equipment as the piping diameters are smaller. The largest stacks are the LH2 vent stacks on trailers and on tanks for the main safety valves are 3”. For GH2 systems the flare stacks are generally smaller in diameter.

Flaring is a deliberate ignition of a hydrogen stream. If the hydrogen stream is to be ignited, the timing of the ignition must be exact at the very beginning with a flame igniting the hydrogen before the cloud gets too large and represents a deflagration/detonation danger.

For relief devices, this is very difficult due to the large instantaneous flow rate Flaring is also not typical as:

- A steady and constant flow is needed to maintain ignition

- Reignition explosively is possible if flameout occurs

- Timing of the initial ignition could cause a large cloud to be ignited

If a flare system is used, it must

- Dispose of H2 safely

- Prevent explosions

- Have a steady flow rate or controls that assure ignition is maintained. Variable

velocities indicate a flare stack may not be advisable. - Control the flare to assure

- Pilot ignition

- Flameout warning systems

- Limit the backflow of air into the stack

- Flame dip does not occur

- Variable velocities can cause

- Flame blowout/burn-off - High velocity

- Flame Dip -Allows air into the larger vent system- Low velocity

API 521 is a code that addresses flaring, besides the ANSI document.

There is some information on vent stack flaring below. The ANSI/AIAA G-095A-2017 Guide to Safety of Hydrogen and Hydrogen Systems former NASA NSS 1740.16 document addresses vent stack flow rates for flaring.

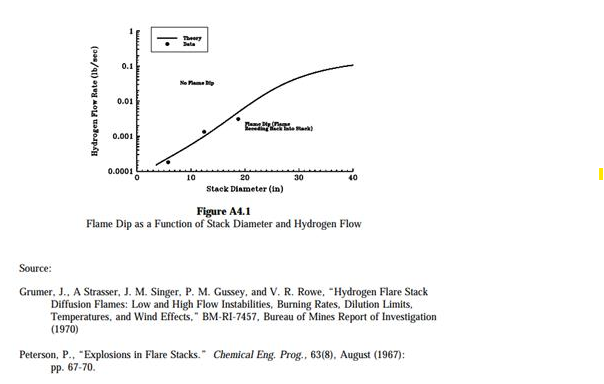

This document states “Quantities of hydrogen of 0.113 to 0.226 kg/s (0.25 to 0.50 lb/s) have been successfully vented from a single vent 5 m (16 ft) high”. .226 kg/s is a very large flow rate (340,000 scfh/8000 nm3/hr). Per NASA Figure A4.1, there is no flame dip shown (flame receding into the vent stack) below a 3 in stack size, which is consistent with the best practices.

The flare systems themselves must incorporate pilot ignition, flameout warning mechanisms, and a means to purge the vent line, ensuring comprehensive safety measures are maintained throughout the process.